The latest news from Setaram

Whether a seminar, market news, new content, upcoming trade shows, product innovation, promotions, customer feedback or other topical news and events, we strive to keep you informed

Filter by category:

20% discount on our Setline DSC and Setline STA*

Categories: Product & Brand

Excerpt: Need a 20% discount on simple & powerful thermal analysis instruments ?

Webinar – Hydrogen

Categories: Webinar

Excerpt: Hydrogen is a clean source of energy, and it plays an important role in mitigating environmental challenges as well as facilitating the transition into a more sustainable future.

Webinar – Corrosion

Categories: Archives

Excerpt: Thursday,March 21st (10:00 – 11:00 AM GMT+1) – Webinar: How to test materials protection against high temperature corrosion? Live webinar using Microsoft Teams Many industrial…

Webinar – Metals & Ceramics

Categories: Archives

Excerpt: Thursday,February 22nd (1:00 – 1:30 PM Eastern Time) – Webinar: Thermal Analysis for the Characterization of Metals and Ceramics Live webinar using Microsoft Teams Thermal…

2024 Webinar program

Categories: Webinar

Excerpt: Register now for an upcoming webinar (depending on your timezone):

Webinar – Batteries

Categories: Archives

Excerpt: Thursday, November 30th (1:00 – 1:30 PM Eastern Time) – Webinar: Calorimetry and thermal analysis for better batteries Live webinar using Microsoft Teams In the…

Webinar – Batteries Thermal Safety

Categories: Archives

Excerpt: Thursday, October 26th (10:00 – 10:30 AM GMT+2) – Webinar: How to improve batteries thermal safety ? Live webinar using Microsoft Teams In our world…

Webinar – Corrosion Materials

Categories: Archives

Excerpt: Thursday, September 28th (1:00 – 1:30 PM Eastern Daylight Time) – Webinar: How to test materials protection against corrosion? Live webinar using Microsoft Teams Corrosion…

Webinar – Green materials

Categories: Archives

Excerpt: Thursday, September 21 (10:00 – 10:30 AM GMT+2) – Webinar: Thermal Analysis and Calorimetry for green materials & processes Live webinar using Microsoft Teams Global…

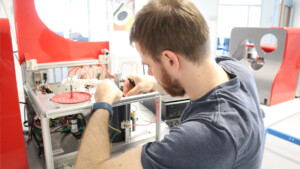

Robots designed by humans

Categories: Applications & Technologies

Excerpt: For more than 10 years, the KEP Technologies Group has been developing from A to Z autosamplers for its thermal analyzers, to meet the needs…

The EPFL School of Physics talks about our Themys One

Categories: People

Excerpt: TESTIMONIAL Pr. Daniele Mari Deputy Director of the School of Physics. Adjunct Professor. Responsible for Student Laboratories. Few minutes to spare? WATCH TESTIMONIAL EPFL…

Webinar – Methods for reliable tests

Categories: Archives

Excerpt: Thursday, May 25 (1:00 – 1:30 PM Eastern Daylight Time) – Webinar: More reliable thermal analysis tests with standardized methods Live webinar using Microsoft Teams…